Zhongshan Jinlei Electroni Technology Co., Ltd

Zhongshan Jinlei Electroni Technology Co., Ltd

Zhongshan Jinlei Electroni ttc Technology Co., Ltd.was founded in 2003 with a registered capital of 4.8 million yuan and a plant area of 12500 square meters. The company is located in Zhongshan City, Guangdong Province, which is a famous historical and cultural city in China. It specializes in the research and development, design, production and sales of LED lighting, small household appliances, silica gel products, hardware and plastic products and accessories. And provide professional lighting engineering solutions and comprehensive services of the photoelectric technology industry company.

The company is committed to designing, manufacturing and selling all kinds of household, commercial and engineering lighting products, with good manufacturing capacity and perfect R & D system.

Workshop

display

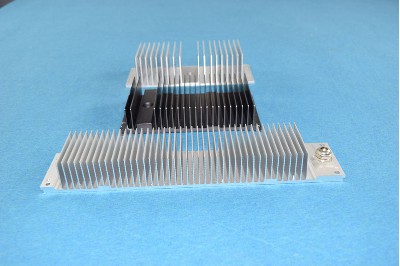

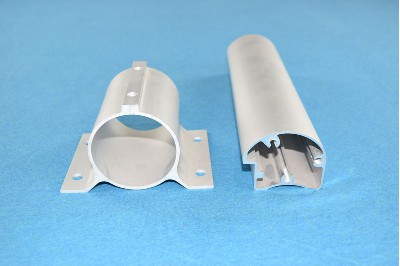

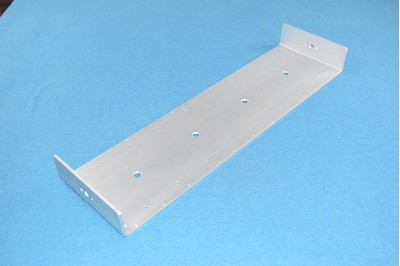

Product Center

Always focus on providing customers with high quality services and products

Industry News

MORE+

How to test metal stamping parts

2020-05-05

What is the influence on the quality of metal stamping parts

2020-05-05

How to test metal stamping parts

2020-05-05

What properties should metal stamping molding sand have

2020-05-05

How to check the quality of metal stamping parts

2020-05-05

What are the processes of metal stamping parts

2020-05-05

What are the processing technologies of metal stamping

2020-05-05

Common problems

MORE+

What are the basic processes of metal stamping

The primary basic processes of stamping are blanking, punching, zigzag and deep drawing.(1) blanking and punching blanking and punching are processes to separate the blank.The process of blanking and punching is completely the same except for different purposes. When blanking, the separated part is the product, and the rest of the surrounding is the waste; punching is to obtain holes, the punched

How to test the hardness of metal stamping parts

Hardness test of metal stamping parts Rockwell hardness tester is selected for hardness test of metal stamping parts. The small stamping parts with disordered shape can be used to test the small plane and can not be tested on the ordinary Rockwell hardness tester. Metal stamping processing includes stamping, zigzag, drawing, forming, finishing and other processes.Hardness test of metal stamping pa

What are the common problems in metal stamping

I. in the daily processing of metal stamping parts, there will be problems such as large or small punch size and large difference between punch size and punch size.2. When the cutting edge is worn, the tensile stress of the data increases, and the tendency of turning over and distortion of the stamping parts increases. When turning over occurs, the punching dimension will be smaller.3. The strong

Cooperative Partner

Improve business profitability and create great value together with customers